Product Overview

BenefitsDesign Features Downloads & Links

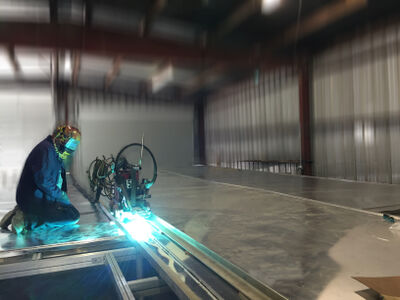

The Aluminator WD (Welded Deck) internal floating roof is the premier solution among low-emissions aluminum IFRs. Built on the proven structural components of the Aluminator 1000 heavy-duty AIFR, but with sheeting joints welded instead of bolted, this roof qualifies as welded construction per US EPA requirements. The Aluminator WD has several advantages over welded-panel-based AIFRs, including decades of proven history in both the structural and buoyancy systems, emissions welds that are raised out of the product, and a more economical installation price.

1/1